EQI Berea

Facility

The EQI Berea facility offers industrial coating and warehousing services, in addition to a variety of value-add services that help you streamline your operations. These capabilities include powder coating, wet paint, assembly, repair services, sequenced delivery, and more.

Services

Industrial Coating, Warehousing, Manufacturing, Assembly, Repair, Just-in-Time Delivery

Key Services

Industrial Coatings & Integrated Warehousing

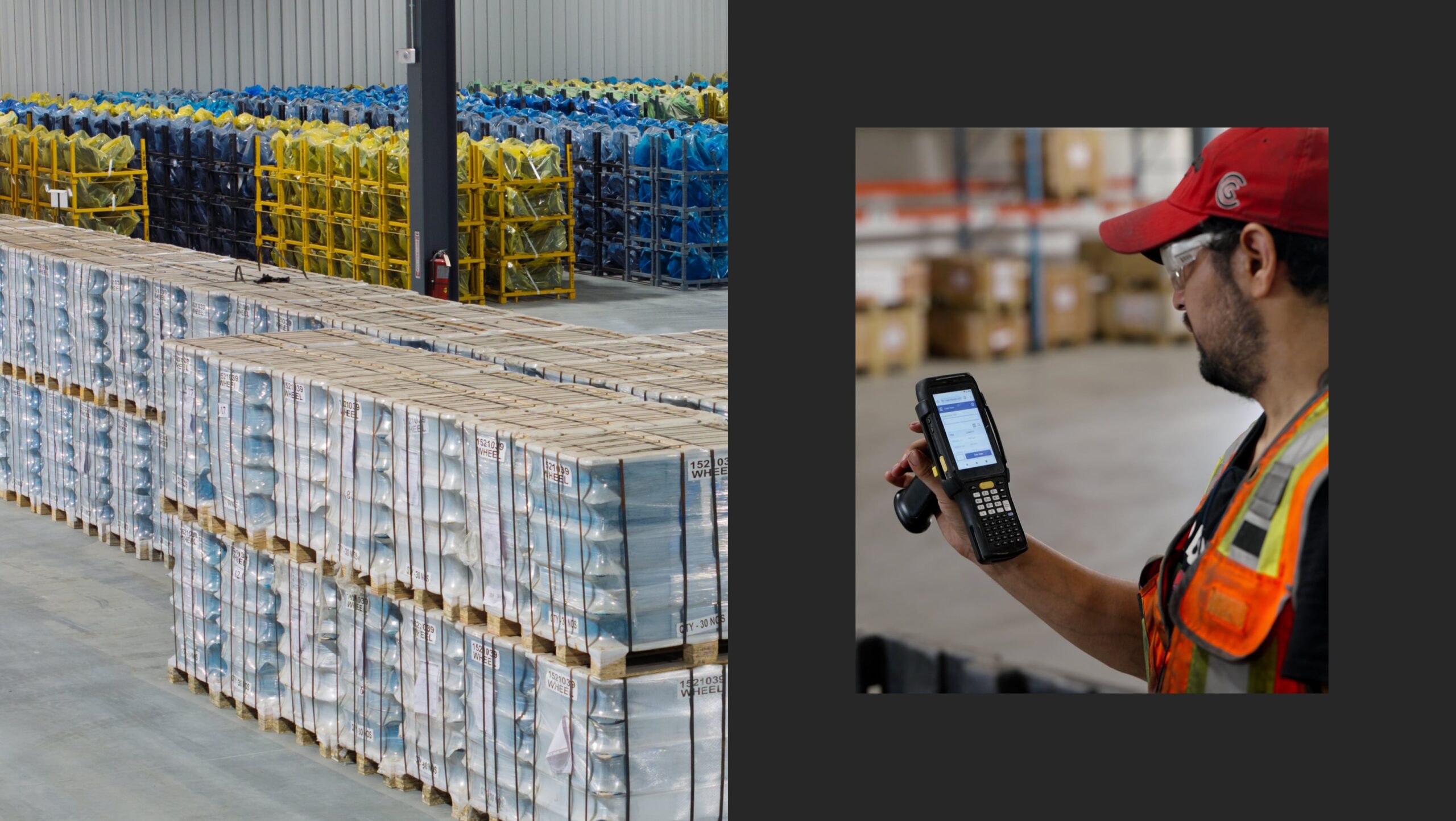

In addition to providing specialized industrial coating services, our Berea facility is an expansive, high-capacity, high-tech warehousing and distribution hub for global OEMs.

91,650 sq ft

Production and warehousing

space under the same roof

2

Fully automatic powder coat

booths on our main line

450 parts

Powder coated in an

8-hour shift

3 acres

Dedicated outdoor storage

Industrial Coatings

Powder Coating

Our Berea facility provides specialized powder-coat services engineered for quality, efficiency, and agility. Every product undergoes either an automatic four-stage wash and pre-treatment or blasting process to properly prepare the substrate for superior adhesion and durability. Our lines offer flexibility for large repetitive production runs as well as custom and small-batch color requirements.

Our powder coat line offers two automatic paint booths for high-efficiency, standard-color coating, and one manual booth for non-standard, small-batch colors.

Our size envelopes can accommodates the following component dimensions and weights:

• 6.9 ft x 4 ft x 1.3 ft, 220 lbs. per hook

• 11.5 ft x 4.9 ft x 6.6 ft, 6,600 lbs. per hook

Using an advanced reclamation process, we recover 95% of powder from the two automatic booths and recycle it to support our sustainability goals.

Industrial Coatings

Wet Paint

From tiny parts to large counterweights and full machines, we can expertly paint any component at any scale.

One large wet paint booth, with plans to expand to a total of five in the next year.

Capacity to paint 120+ counterweights each day.

Inventory Management & Warehousing (WMS)

Utilizing a data-enriched warehouse management system, our Berea facility streamlines inbound and outbound workflows to make inventory management efficient, accurate, and dependable. With vast indoor and outdoor space, we can store in-process or finished components of any size, enabling just-in-time and sequenced deliveries.

Our expansive outdoor storage space is ideal for large components like counterweights, vehicle frames & cabs, booms and masts.

Our racking and floor storage system is designed to accommodate 500 pallet spaces, with expansion to 1,750 planned in 2026.

Additional Services

Berea Value-add Services

Repair Services

We provide repair, rework and repainting services for your critical assembly components to help you save time and expense of purchasing new parts.

Part Testing & Inspection

We receive parts from our global supply network and rigorously test and inspect them for quality and performance.

Kitting

We furnish precise component kitting that meets your exact specifications, delivering line-ready components that ensure efficiency and speed for your production process.

Assembly Services

The EQI team can expertly assemble your painted components, including hoods and panels, giving you more time to focus on what you do best.

Contact

Get in touch with EQI Berea

Facility Contacts

David Tucker

Warehouse Manager

Richard Graham

Vice President of Value-Added Services

Michael Koch

Vice President of Operations