Introducing EQI Specialty Products

Two companies with decades of thermal-processing experience, united with EQI to deliver the highest level of quality, service, and innovation

Combining Decades of Thermal-Processing Experience

For over 20 years, EQI has been a leading provider of line-ready metal components and innovative supply-chain solutions. Today, EQI has added a new division—EQI Specialty Products. This suite of products and services combines the deep thermal-processing expertise of Ferralloy, Inc. and Pro-Tech with EQI’s global sourcing, quality assurance, and line-ready delivery capabilities. The result is a broader, stronger platform for customers who need heat-resistant alloys, forgings, castings, and engineered fabrications that perform in extreme environments.

Expanding EQI’s Product Capabilities

By uniting Ferralloy, Inc. and Pro-Tech into one powerful division, EQI is better equipped to deliver exceptional value to its customers.

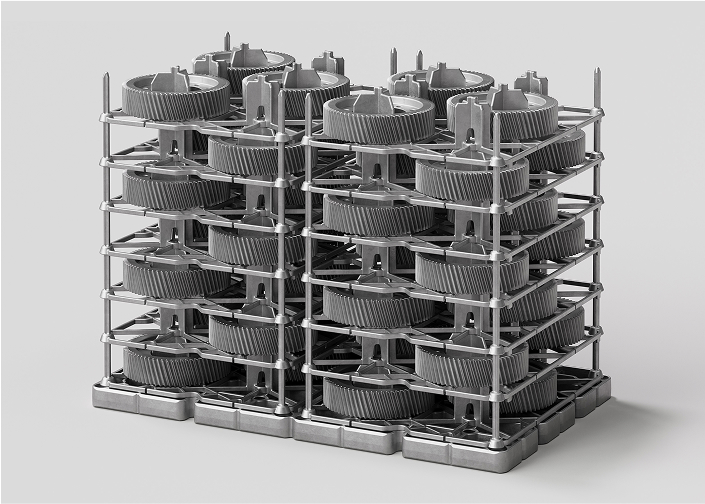

Established in 1984, Ferralloy, Inc. initially focused on heat-resistant alloy castings and fabrications used primarily in the thermal-processing industry. Since then, the company has evolved its offering to include closed-die and rolled-ring forgings, investment castings, machined bar stock components, exotic superalloys, and refractory alloys in all shapes and sizes.

Pro-Tech, founded in 1985, helps position EQI as a leader in the thermal-processing business with its reputation for supplying high-temperature products to various sectors, including heat treating, steel production, lime production, cement production, and power generation.

Empowering EQI to Serve New Customers

In addition to expanding EQI’s product line, Ferralloy, Inc. and Pro-Tech enhance EQI’s customer base and expand its supply network. Ferralloy, Inc. serves multiple markets, including metal processing (heat treatment, fabrication shops, machine shops), automotive, aerospace, mining, and heavy equipment. The company also maintains relationships with world-class customers, including Caterpillar, Ford, Owens Corning, Mack, and Whirlpool, as well as strategic suppliers in China, India, and the US.

Pro-Tech serves a diverse customer base of more than 100 clients, ranging from commercial heat-treaters to major players in heavy-duty truck manufacturing, power generation, automotive, and aerospace industries with captive heat-treating operations. With 90 percent of its revenue originating in the United States—and additional contributions from Mexico and Canada—Pro-Tech has expanded its global footprint while maintaining a robust domestic presence.

Delivering the Highest Level of Service Together

Over the years, EQI has become a leading provider of customized solutions to meet customers’ complex manufacturing needs. The company simplifies processes and mitigates risk by thoughtfully evaluating each customer’s challenges and matching them with the best capabilities and partners for each project. To achieve this, EQI leverages its global manufacturing network, producing a diverse array of line-ready metal components.

Through EQI Specialty Products, longtime Ferralloy, Inc. and Pro-Tech customers will benefit from EQI’s enhanced operational efficiencies, resilient supply chains, and rigorous focus on quality—along with the high level of thermal processing expertise they’ve come to expect.

Contact Us

For additional details on how EQI’s new capabilities can assist you, please contact us below.

Honoring QEM for 20 Years of Excellence in Precision Machining

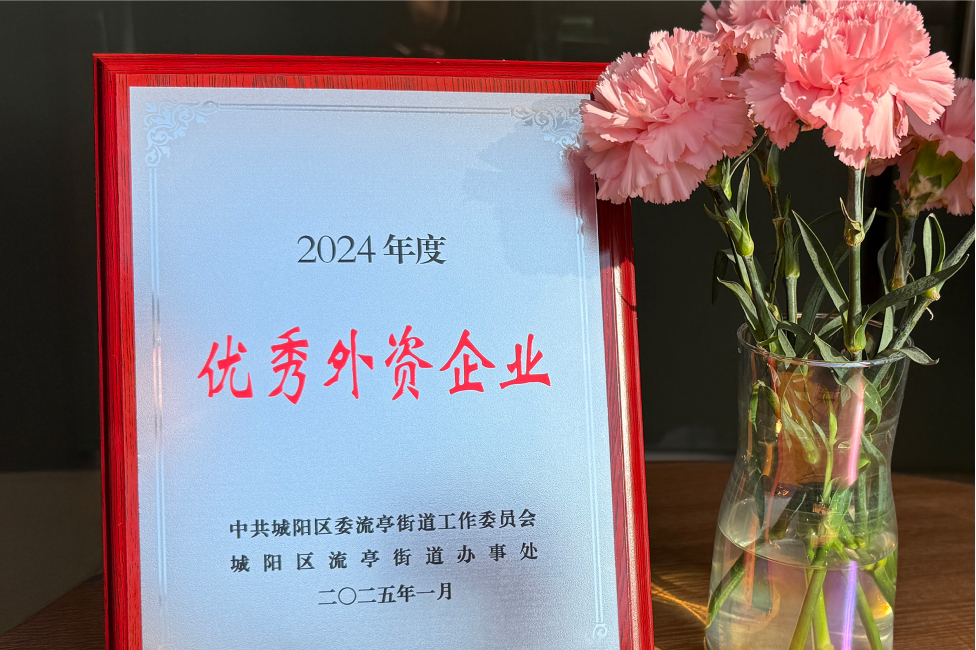

At EQI, we recently celebrated our 20th anniversary. Today, we’re excited to share this milestone with one of our key Chinese finishing facilities—Qingdao Effort Machining Co. (QEM). Over the past twenty years, QEM has set the standard for quality, efficiency, and growth as one of EQI’s most trusted global sources for line-ready metal components.

Contact Us

Send us a message and someone from EQI will get back to you as soon as possible.

Resilient Supply Chains—Built in India, Delivered by EQI

In today’s volatile global trade environment, what’s your plan if tariffs spike or your key suppliers become unavailable? Two of the largest manufacturers in the U.S.—a leading aerial work platform OEM and a top-three lift truck maker—didn’t wait to find out. Instead, they turned to EQI to build resilient, diversified supply chains rooted in India.

The Challenge

From rising tariffs to pandemic-era shipping chaos and environmental shutdowns in China, our customers were facing increasing pressure to secure their supply of critical castings—particularly high-volume counterweights. They needed a trusted partner with boots on the ground, deep engineering know-how, and the capability to qualify and manage new suppliers quickly. EQI stepped in with a proven plan.

The Solution

Well before global headlines made diversification urgent, EQI began investing in an India-based supply chain strategy. Since 2014, we’ve developed and qualified multiple Indian foundries capable of delivering large, high-specification counterweights. For our two anchor customers, we led a phased transition that started with their highest-volume SKUs.

For our two anchor customers, we led a phased transition that started with their highest-volume SKUs. EQI handled:

- • New tool builds, tooling transfers, and local production readiness

- • Sample production and part approval processes

- • Capacity planning and logistics coordination

- • Continuous supplier quality audits and engineering support

Even during the most turbulent supply chain periods, we helped them shift 25–30% of their tonnage to India—giving them the flexibility to maintain production when others couldn’t.

The Results: Scalable, High-Quality Indian Sourcing

As of 2025, these customers are now sourcing 60–70% of their counterweight needs from India, and that number continues to rise. Our infrastructure supports rapid expansion thanks to:

- • Three qualified Indian foundries already producing for U.S. OEMs

- • 40+ unique SKUs launched and supported over the last eight years

- • 80% of total casting tonnage now approved for Indian production

With Indian operations already integrated, our customers are ready to mitigate the next wave of tariffs without delay.

EQI-owned Berea, KY counterweight coating and distribution facility

EQI-owned Williamsport, MD counterweight coating and distribution facility

What It Looks Like for You

We’ve built the roadmap—and we’re ready to lead you through it. EQI’s India-based supply chain services are backed by our engineering, procurement, and logistics teams in both the U.S. and India. That means faster transitions, better visibility, and consistent quality. Most importantly, we have the capacity to scale and support future movements to India.

Here’s how fast your shift to India can happen:

Contact Us

Whether you need a full-scale transition or a risk-mitigation dual source, EQI has the capacity, experience, and supplier network ready to go. Interested in learning more about building resilient supply chains? Let’s talk.

Five Things to Look for When Outsourcing Your Metal Component Manufacturing

Finding a reliable resource for your metal component manufacturing can feel like an overwhelming challenge, but it doesn’t need to be. After years of experience working with leading OEMs, we’ve developed a list of the top five essential qualities of a manufacturing partner that will simplify your job and enhance your operations’ efficiency.

1

Nimble and multi-sourced

Given the uncertainty many OEMs face today, you need a nimble partner with flexibility across their supply chain with access to multiple points of origin. A forward-thinking supplier will have already established a multi-sourced manufacturing network, allowing them to match you with the best capabilities and partners for your project.

2

Able to consolidate services

Along with supply chain flexibility, consolidation of services is another essential quality to look for in a manufacturing partner. From engineering to production, machining, coating, and packaging, find a supplier who can coordinate and streamline all these logistics and do them more efficiently at scale.

A consolidated suite of services should also include inventory management. An ideal partner should be so entrenched in your day-to-day operations that they can provide insights into your consumption patterns, helping you keep the right products in the right places at the right time.

If the supplier is physically located near your operations, even better. Your manufacturing partner should have the facilities to warehouse your components, allowing you to gain efficiencies through just-in-time manufacturing and delivery. This approach saves you money, since you only have to pay for the components when you actually need them. You get the flexibility of having inventory on hand, but you can use your square footage to expand your operations and grow your customer base.

3

Provides a broad scope of capabilities and expertise

Some manufacturers will tell you they are experts in the products they supply, but the scope of products they offer is limited. You need a partner with the expertise and ability to go broader and a proven track record of producing various metal components using any type of metal and manufacturing process.

In the long term, your manufacturing partner should become an important part of your metal component product development team, so you can look to them for guidance on the best material and most efficient, cost-effective process for producing your products.

4

Ensures quality and efficiency with boots on the ground

Another reason it’s important to find a manufacturing partner who is physically located near your operations is that proximity allows them to control production at the source. Many companies will send people to do quality audits once a year. Still, you need a partner with experts in development, engineering, production, and customer service who are fully embedded with your team and have in-depth knowledge of your components and manufacturing processes.

Other on-site services to look for include project management, a full range of testing options to ensure the highest level of quality, and experts who can help you identify, inspect, audit, and select other qualified manufacturers to work with.

5

Easy to work with via digital tools

Perhaps one of the most important questions you can ask when searching for a manufacturing partner is, “Are they easy to work with?”. A good partner should have a digital platform that addresses everything from product development through order management and allows you to look up the status of new projects and invoices, launch RFQs, and more. Also, be sure they have the software to detail out all cost elements of a product, providing you with total transparency and confidence.

Contact Us

Interested in learning more about how EQI is uniquely positioned to help you? Let’s talk.

EQI Acquires Ferralloy, Expanding Thermal Capabilities

The EQI team is excited to announce that we’ve recently acquired Ferralloy, Inc., a leading global supplier of heat-resistant alloy products, forgings, production castings, and specialty raw materials. Over the past few years, EQI expanded its capabilities by acquiring Pro-Tech, a prominent supplier of metal products to the thermal processing industry. Together, Ferralloy, Inc., and Pro-Tech will add scale to EQI operations and diversify EQI products, services, customer base, and supply chain.

Established in 1984, Ferralloy, Inc. is based in Cleveland, Ohio. When the company was founded, it focused on heat-resistant alloy castings and fabrications used primarily in the thermal processing industry. Ferralloy Inc. has experienced substantial growth in the years since, expanding its offering to include closed-die and rolled-ring forgings, investment castings, machined bar stock components, exotic superalloys, and refractory alloys in all standard shapes and sizes.

Ferralloy, Inc., serves multiple end markets, including metal processing (heat treatment, fabrication shops, machine shops), automotive, aerospace, mining, and heavy equipment. Through commitment to process improvement, quality, and customer satisfaction, along with ISO 9001 certification, Ferralloy, Inc., has established a world-class customer base, including Caterpillar, Ford, Owens Corning, Mack, Whirlpool, and more. The company has also cultivated valuable supply relationships in China, India, and the US, enhancing the EQI global network assurance, testing, and logistics and inventory management services.

We are confident that the acquisition of Ferralloy Inc., which will operate as a division of EQI, will enhance the company’s ability to deliver the highest level of quality and service to its customers. Their expertise and capabilities in thermal processing and their focus on quality will drive innovation at EQI and better equip us to deliver exceptional value to our customers.

Contact Us

For more information about Ferralloy, Inc. please visit ferralloy.com. For additional details on how EQI’s new capabilities can assist you, please contact us below or give us a call at 616.850.2630.

What’s the Best Metal for Your Casting Project?

EQI has been a leading supplier of metal castings for decades. Castings allow for the cost-effective creation of complex, three-dimensional parts to meet almost any application’s requirements. While all casting processes begin with molten metal, a variety of specialized molding processes are best suited to specific materials and part attributes.

Investment

Casting

Uses a wax pattern coated with a refractory material. Then, the wax is melted out and the mold is filled with molten metal.

Techniques:

- Silica sol process

- Combination process with silica sol – sodium silicate

Sand

Casting

Uses sand as the main mold material.

Techniques:

- Vacuum process sand

- Green sand casting

- Resin-bonded air or gas set sand casting

- Thermal set sand casting (shell molding)

- Lost foam

Die casting / Permanent Mold /

Semi-Permanent Mold

Uses metal molds and high pressure to force the molten metal into a mold.

Techniques:

- High-pressure casting

- Low-pressure casting

- Gravity pour casting

When selecting metal for a casting project, EQI will work with you to consider characteristics such as strength, hardness, machinability, corrosion resistance, and cost. With these factors in mind, EQI offers a broad range of iron, steel, and aluminum castings across nearly every casting manufacturing process.

Iron

Grey Iron

Known for its color, which comes from the graphite flake structure that develops during the solidification process. Grey iron is a popular choice because it’s cost effective.

Qualities

- Good machinability

- Great damping capacity

- Good thermal conductivity

Uses

- Pump housings

- Gears and valves

- Hydraulic parts

- Machinery bases

Ductile Iron (Nodular Iron)

A cast iron with spherical graphite structures in the metal that increase ductility and broaden the range of suitable applications. Stronger than grey iron, ductile iron can be alloyed to boost specific properties such as thermal resistance, strength, and elongation. Due to its high carbon content, ductile iron is a good candidate for various heat treatments to modify the microstructure and material properties further.

Qualities

- High tensile strength

- Superior ductility and improved impact resistance

- Excellent wear resistance

Uses

- Heavy-duty machinery components

- Critical structural and load-bearing components

- Hydraulic parts

- Machine tooling

- Fittings

Steel

Carbon and Alloy Steel

Steels can be tailored for many applications by selecting the appropriate carbon and alloy content. Heat treatment can provide a wide range of strength, ductility, and hardenability. Carbon steel is versatile and economical, making it ideal for general machine and structural applications. It can also be easily welded up to specific levels of carbon equivalence.

Qualities

- High tensile strength

- Great ductility

- High machinability

Uses

- Industrial equipment

- Construction components

- Machinery parts

Stainless Steel

A ferrous alloy that is highly resistant to oxidation and corrosion due to added chromium that forms a protective oxide layer. There are over sixty different grades of stainless steel, and unique compositions are regularly added to the spectrum.

Qualities

- Corrosion resistance

- High strength

- Toughness

- Excellent thermal resistance

- Suitable in harsh environments (heat, cold, acidic) and hygiene applications

Uses

- Chemical processing equipment

- Pumps & valves

- Impellers

- Housings

Nickel-Based Alloys

These alloys are often deployed in extreme working environments. The nickel matrix and alloying additions perform exceptionally in high-temperature and corrosive applications, often in the thermal processing, chemical, and petroleum industries.

Qualities

- Thermal resistance

- Corrosion resistance

Uses

- Industrial furnaces

- Water treatment components

- Marine parts

- Chemical processing equipment

Aluminum Alloys

Aluminum alloys have a desirable strength-to-weight ratio, making them ideal for applications where weight is an issue.

Qualities

- High strength-to-weight ratio

- Good corrosion resistance

Uses

- Transportation parts

- Industrial components

- Marine applications

Contact Us

EQI is ready to help you determine which metal alloy best suits your needs. Get started with help from our metal casting experts.

Adding Value Through New Coating Guarantees at Northern Ireland Facility

At EQI, we continuously tailor our value-added services to meet our customers’ needs. An excellent example comes from our facility in Craigavon, Northern Ireland, which is proud to offer high-quality powder coating services with standard and marine grade guarantees of up to 40 years.

Recently, the Craigavon facility earned new certifications for coating architectural aluminum, ensuring adherence to the highest quality standards for our customers. The Craigavon team has been designated approved applicators with Akzo Nobel, Sherwin-Williams, and Axalta powders for coating all architectural aluminum products up to 8 meters long.

Here are a few more reasons why customers can rely on Craigavon to deliver exceptional coating services for architectural aluminum.

Offer standard and marine grade guarantees for at least 25 years and up to 40 years on specific coatings through our five-stage dip pretreatment process. This is especially valuable to our customers located near the ocean and challenged by high levels of moisture and salt sea air.

Utilize onsite lab equipment for daily testing to ensure products meet rigorous global architectural standards.

Verify quality through in-depth techniques, including salt spray corrosion tests, impact and abrasion resistance tests, and adhesion checks.

Have a high capacity to process aluminum louvers, cills, flashings, and facades in our advanced semi-automatic powder line.

Able to fulfill specific requirements for packaging, storage, and delivery to you and your customers.

Craigavon is just one example of a facility that’s adding value through employees who’ve become masters of their craft. Says Daniel Courtney, General Manager at Craigavon, “There’s nothing in the market we can’t paint, and if we haven’t done it before, we will always give it a go.”

The Craigavon team has also created a family-like atmosphere, working to develop personalized relationships with each other and customers. The casual, laid-back culture has fostered an environment where everyone–from the person working on the shop floor to upper management–feels as though they have an equal stake in contributing to the company’s success.

Contact Us

If you’re looking for an approved applicator for powder coating and wet paint—who will treat you like family—fill out this form or call us at +44 28 3835 1302, or (616) 850-2630.

The Truth About Tariffs

Why EQI is uniquely positioned to handle any type of supply chain risk.

We’ve all heard the news about the tariffs, and many of you have come to us with concerns. How will these tariffs affect us? Where is the right place to do business?

Our answer to these questions is simple. Tariffs are just another type of supply chain disruption, and we at EQI are the most effective company in the world at mitigating risk for your metal components.

From the pandemic to environmental crises, government sanctions, and beyond, we have swiftly navigated every type of challenge you can imagine–including tariffs implemented by previous administrations.

We thoughtfully evaluate each customer’s challenges and create custom solutions, matching them with the best capabilities and partners for each project. To achieve this, we leverage our global manufacturing network, which empowers us to produce a diverse array of line-ready metal components that fulfill unique product needs.

Let’s take a look at a few more reasons why EQI is uniquely capable of mitigating risk:

- Top-three global counterweight provider with years of experience managing risk.

- A leadership team that brings decades of experience in production, procurement, logistics, supply chain management, and more.

- Spent over 20 years developing an extensive supply chain in China and have maintained strong relationships with production partners there. China continues to produce high-quality, lower-cost products, even with the tariffs.

- Developed strong partnerships with suppliers in India, Vietnam, and North America, doubling our capacity and enhancing our ability to swiftly source outside of China as needed.

- Established global logistics and shipping partners. Other competitors in this market don’t have the same type of access to large-scale options. For example, EQI ships over 8,000 containers per year.

When you partner with EQI, you gain access to a comprehensive range of capabilities. We will expertly handle your shipping and logistics and offer value-added services such as coatings, warehouse and inventory management, machining, and assembly.

This extensive range of services simplifies supply chains and provides certainty, transparency, and resiliency in the face of any type of risk.

Contact Us

Interested in learning more about our risk mitigation capabilities? Contact us today.