Introducing EQI Specialty Products

Two companies with decades of thermal-processing experience, united with EQI to deliver the highest level of quality, service, and innovation

Combining Decades of Thermal-Processing Experience

For over 20 years, EQI has been a leading provider of line-ready metal components and innovative supply-chain solutions. Today, EQI has added a new division—EQI Specialty Products. This suite of products and services combines the deep thermal-processing expertise of Ferralloy, Inc. and Pro-Tech with EQI’s global sourcing, quality assurance, and line-ready delivery capabilities. The result is a broader, stronger platform for customers who need heat-resistant alloys, forgings, castings, and engineered fabrications that perform in extreme environments.

Expanding EQI’s Product Capabilities

By uniting Ferralloy, Inc. and Pro-Tech into one powerful division, EQI is better equipped to deliver exceptional value to its customers.

Established in 1984, Ferralloy, Inc. initially focused on heat-resistant alloy castings and fabrications used primarily in the thermal-processing industry. Since then, the company has evolved its offering to include closed-die and rolled-ring forgings, investment castings, machined bar stock components, exotic superalloys, and refractory alloys in all shapes and sizes.

Pro-Tech, founded in 1985, helps position EQI as a leader in the thermal-processing business with its reputation for supplying high-temperature products to various sectors, including heat treating, steel production, lime production, cement production, and power generation.

Empowering EQI to Serve New Customers

In addition to expanding EQI’s product line, Ferralloy, Inc. and Pro-Tech enhance EQI’s customer base and expand its supply network. Ferralloy, Inc. serves multiple markets, including metal processing (heat treatment, fabrication shops, machine shops), automotive, aerospace, mining, and heavy equipment. The company also maintains relationships with world-class customers, including Caterpillar, Ford, Owens Corning, Mack, and Whirlpool, as well as strategic suppliers in China, India, and the US.

Pro-Tech serves a diverse customer base of more than 100 clients, ranging from commercial heat-treaters to major players in heavy-duty truck manufacturing, power generation, automotive, and aerospace industries with captive heat-treating operations. With 90 percent of its revenue originating in the United States—and additional contributions from Mexico and Canada—Pro-Tech has expanded its global footprint while maintaining a robust domestic presence.

Delivering the Highest Level of Service Together

Over the years, EQI has become a leading provider of customized solutions to meet customers’ complex manufacturing needs. The company simplifies processes and mitigates risk by thoughtfully evaluating each customer’s challenges and matching them with the best capabilities and partners for each project. To achieve this, EQI leverages its global manufacturing network, producing a diverse array of line-ready metal components.

Through EQI Specialty Products, longtime Ferralloy, Inc. and Pro-Tech customers will benefit from EQI’s enhanced operational efficiencies, resilient supply chains, and rigorous focus on quality—along with the high level of thermal processing expertise they’ve come to expect.

Contact Us

For additional details on how EQI’s new capabilities can assist you, please contact us below.

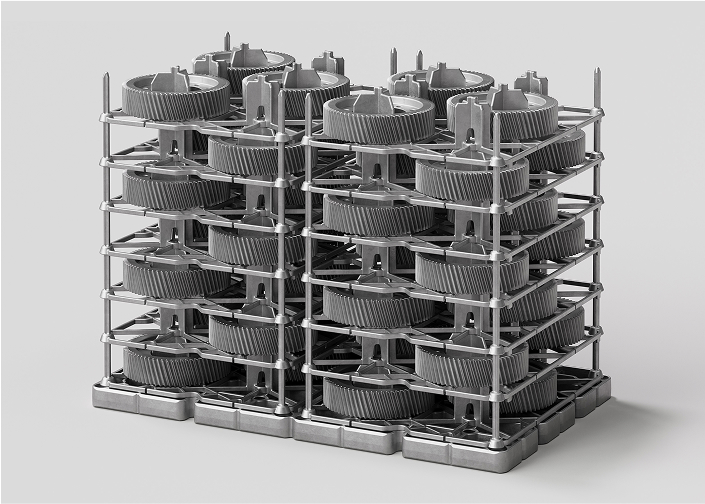

How You Can Save Time and Money with Cast Baskets

When it comes to the baskets your operation uses for heat treating and thermal processing, it may seem easier and more foolproof to choose the same bar frame baskets you’ve used for years. Hundreds of our customers, however, will tell you there’s a better way. Our cast baskets are engineered to withstand heavy-duty loading requirements that outlive and outperform traditional bar frame designs.

Are You Still Buying Bar Frame Baskets?

Many of our customers are die-hard bar frame basket buyers. And we do understand the appeal. First, bar frame baskets typically have quick lead times and are affordably priced. There’s no need for tooling to produce them, compared with cast baskets, which can be expensive. That said, there is a tradeoff that comes along with the affordability of bar frame baskets. Bar frame baskets have a lower level of carbon and nickel, which means they lose their integrity and shape in six months to a year. So, while paying less initially, you will purchase bar frame baskets more frequently–ultimately costing you more time and money.

Why Make the Switch to Cast Baskets?

The bar frame baskets you’ve been buying may work for your operation, but you might want to consider a more durable, consistent, heat-efficient option that can optimize throughput.

First, cast baskets hold their shape longer than bar frame baskets and have better heat efficiency. With a life span of one and a half to two years, their improved dimensional stability results in a more consistent end product. This reduces the need for post-processing or rework following the thermal cycle.

By leveraging our expertise in specialized fixturing and our cast baskets, you can achieve optimal loading and surface contact, preventing part deformation. In addition, our cast baskets offer a thinner wall cross-section, providing 7-10 percent more loading capacity than frame-welded basket designs.

When you decide to invest in our cast baskets, our team will help identify the best size, shape, and combination of components to optimize your loads. We will leverage our pattern inventory of hundreds of designs and sizes that fit most base trays and furnace hearths. We also offer a wide variety of premium materials to suit your processing temperatures.

Why Choose Pro-Tech for Cast Baskets?

Pro-Tech has decades of industry experience, with a strong focus on customer service, product design and performance, and personal sales assistance.

Our US-based experts have created a proprietary cast basket design and superior alloy that increases life expectancy by 50 percent. Without frequent basket replacement, your operations will run smoothly for longer. While the initial investment in the cast basket may be higher, you’ll see significant cost savings over the basket’s life.

With metal component experts Pro-Tech and parent company EQI, you can expect the performance guarantee that comes from an ISO 9001 quality system. Our foundry staff and metallurgical team continuously improve existing alloys and create new ones that increase cast products’ overall life and performance. As a baseline, we offer higher nickel content than our competitors, ensuring stronger, more durable basket walls.

When you’re ready to move forward with a Pro-Tech customized solution, the engineering process is easy. Our experts will create the drawing and collaborate with you on approval. Then, we’ll produce and ship your order. Some standard sizes are already in stock, making ordering even easier.

Once you’re in our system, you can participate in our stocking and replacement program. Our decades of experience in inventory management allow us to efficiently track your tray, basket, fixture, and replacement parts, ensuring zero downtime when you need to place an order.

Contact Us

Interested in learning more about cast baskets and improving your operational efficiency? Contact us today.